You can now also have your liquids filled in bottles at Driessen United Blenders

Our customers regularly ask us whether we can fill liquids in consumer packaging (B2C) as well as in B2B bulk packaging. Driessen United Blenders became what it is today by listening to its customers, investing in the future and then growing together. And this is no different. As of this month, you can also have your liquids filled at our plant in consumer packaging. This can be anything from bottles to jars, varying from about 50 ml to 6000 ml.

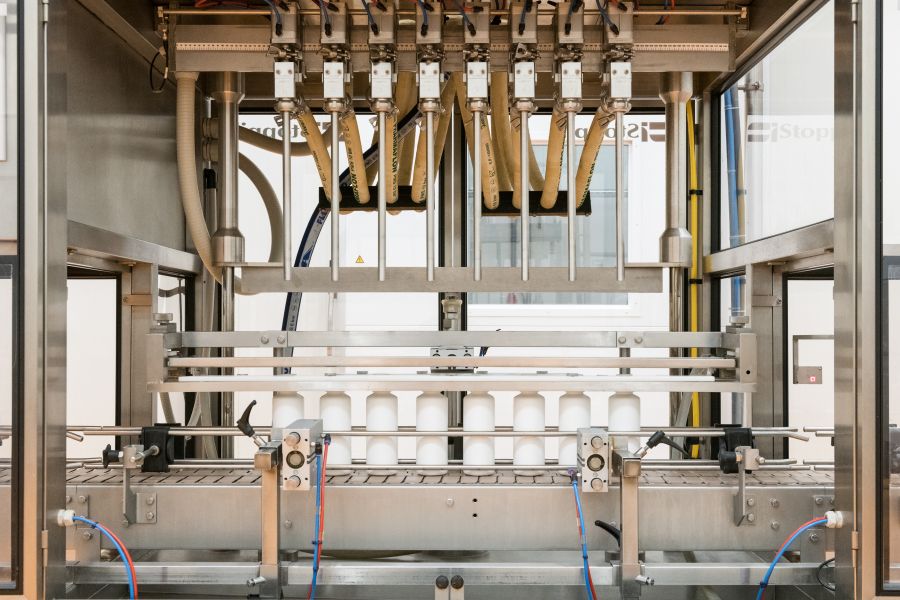

Stoppil filling machine

The filling itself is done with an automatic filling machine manufactured by Stoppil. This filler has 8 heads which, depending on the combined volume required, can fill approximately 2,400 bottles an hour. The filling heads are equipped with flow meters to ensure accurate dosing. A GAF filter is also installed on the line. Another useful option is the ability to first sieve all liquids before filling. After filling is completed, the line is cleaned using an automatic CIP system.

Further options

If desired, gaseous nitrogen can be added after filling to increase the shelf life of the product. To stay flexible for our customers, we have chosen to close the caps semi-automatically. The line is also equipped with an induction sealer and a tamper-evident shrink sleeve for over the cap. As you can expect, we can also apply any desired label on the jar or bottle. This is generally done before the filling process.

more info about the liquid filling line for consumer packaging