our services

Powders and liquids in every conceivable combination

Driessen United Blenders blends powders and liquids in every conceivable combination. We extrude, break, sieve, check, pack and manage the complete storage and logistics of your raw materials and end products.

Blending & stirring

Driessen United Blenders blends every conceivable combination of dry and liquid raw materials for the food industry.

We blend powders with powders, liquids with liquids and liquids with powders (and vice versa). Thanks to our extensive knowledge and experience with stirring and blending, we know how to deal with complex product properties such as delicate, sticky, pasty, unstable and segregation-sensitive raw materials. We select the best techniques from our own range of dosing systems, conical blenders, ribbon blenders, paddle blenders and jetstream blenders. We analyse and check frequently in our own lab. This way you're assured of always getting the right result, whether in terms of quality, costs or efficiency.

Filling, repackaging and packaging

Filling, weighing, repackaging and packing. As a separate service or as part of a complete production process.

Driessen United Blenders packs all types of powders, granulates and liquids into packaging that can range from 200 grams to 25,000 kilos. Regardless of the supply packaging, we repack your product in all types of bags, bottles, jars, round cardboard, drums, IBCs, big bags or tankers. All this in a controlled environment and with a variety of closing techniques. We can use our own neutral packaging or a packaging that you provide us.

As a specialist in packaging, we'd be happy to advise you on the most suitable packaging for your product. Practical, with your own house style and with the look and feel that suits your product or company.

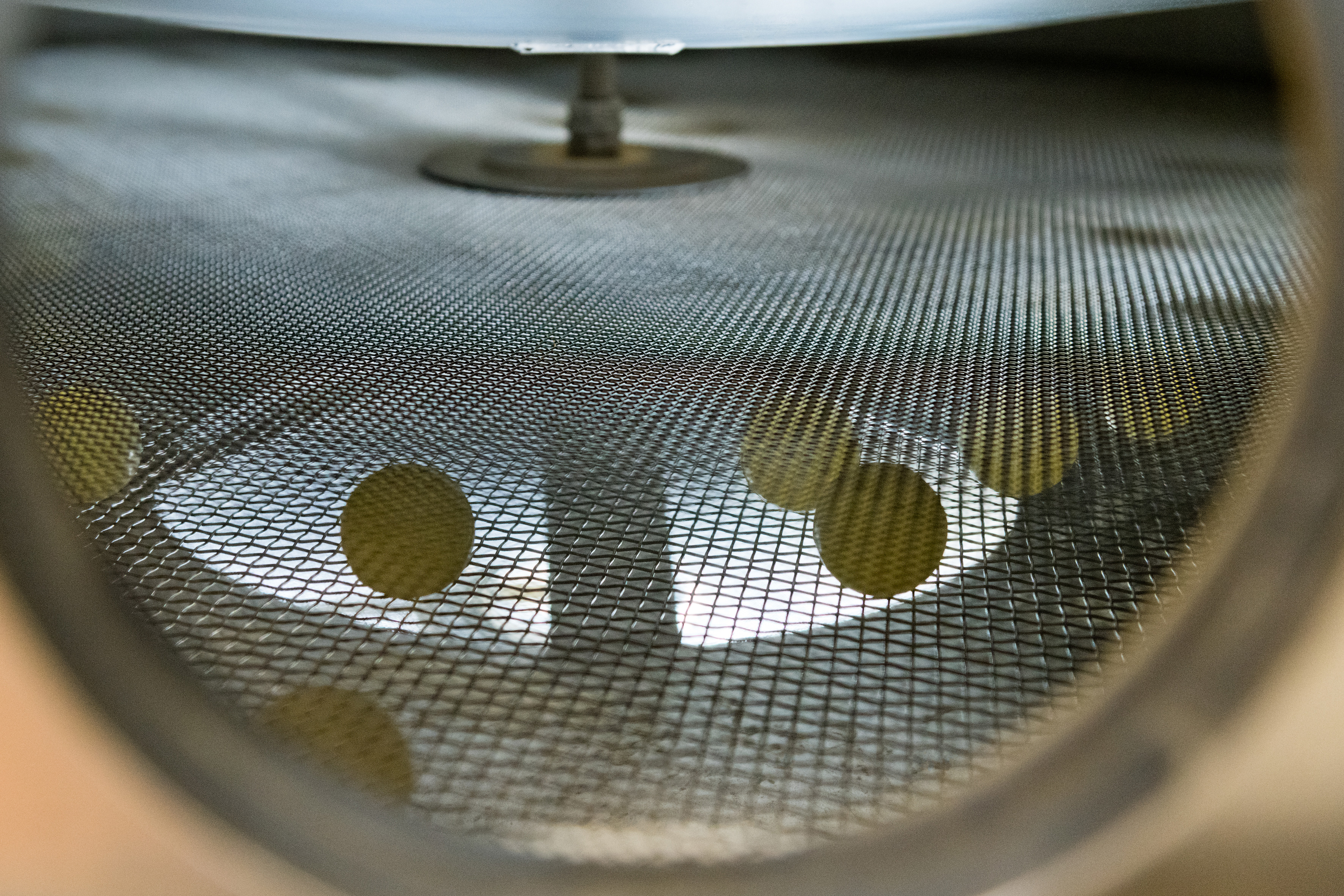

Breaking, sieving and making free-flowing

Blending and filling are often combined with the processes of breaking, sieving and making products free-flowing. This gives you the assurance of having the right product characteristics for the next process step. Depending on your product and the set requirements, we choose the best technique for optimum results. We have shaking, centrifugal and compact vibratory sieves with a very high capacity to remove contaminants, remove dust or separate into up to 4 fractions.

We have years of experience and special techniques for making products free-flowing. Without grinding, we make hardened or agglomerated products free-flowing again to enable further processing.

Extrusion

Our sister company, Driessen Food Extrusion, extrudes the raw materials to create crispy grains, crunchy biscuits, protein chips or coatings. Using our advanced extrusion systems, dryers, coolers, mills and sieves, we design the most suitable modular extrusion line for your product. This modularity allows us to effortlessly vary in composition, size, taste and texture.

Sampling

Many customers of Driessen United Blenders don't get to see their own products. In other words, we are often the eyes and ears for your business during a project. A vital part of this responsibility is sampling incoming raw materials, which safeguards the basic principles of good-quality production. We draw up a sampling and assessment plan together with you. The plan is then put into practice by our trained QC employees.

Only when a raw material has the agreed quality level will it be released for production. Likewise, the end product will only be shipped after the quality of the sample has been approved. We store all samples in accordance with legislation and regulations during the full shelf life of the product.

In addition to carrying out our assessments internally, we would be happy to send samples directly to you, your customer or an (accredited) laboratory of your choice. Driessen United Blenders cooperates with a large number of partners who are recognized in the field of microbiological or chemical research.

Metal detection

Metal detection is a logical step in every production process. The greatest challenge lies in its reliable implementation. Driessen United Blenders uses high-grade metal detection instruments and magnets to detect and remove ferrous and non-ferrous metals. Thanks to our modular production lines, metal detection can be introduced at any desired moment in the production process.